For metal fabrication, welding is a must in most cases. Due to the benefits of using stainless steel in different industries, the skills for welding SS workpieces have increased a lot.

If you are new in the welding community, you have already known about some common metal types and their weldability.

But can you weld stainless steel?

Yes, you can also weld SS (stainless steel) keeping some preparation requirements and suitable weld types in mind. However, the answer needs some explanation that I have given below.

Is It Difficult to Weld Stainless Steel?

Yes, it is difficult to weld stainless steel but not impossible. I have already mentioned the reason for the difficulty which is its heat-retaining characteristics. However, experienced welders don’t have problems with such a property.

Are you having a hard time relating to my statement?

I can understand if the answer is yes. Let me clarify in the following section.

Why Is Welding of Stainless Steel Difficult?

You would know the answer to this question by understanding what stainless steel is. It is an iron-based alloy that contains chromium. The amount or degree of chromium varies from 11%-30% which decides the performance of the alloy. Chromium is the material that makes SS rust-proof.

Welding generates a lot of heat in the process which can easily warp SS bars or sheets. Furthermore, it can get distorted while getting cooled down.

Moreover, any type of welding leaves blemishes and scratch marks on the metal. Here, any wrong steps or shaky hands can lead to scratch marks and blemishes which can’t be restored. Thus, it becomes a problem because lots of people prefer stainless steel for its smooth finish and nice metallic look.

Due to stainless-steel’s unforgiving nature, you can’t make mistakes. It is not possible to hide or make up wrongdoings. That is why beginner welders find it one of the most challenging or difficult welding tasks of all. You can associate it with brain surgeries where mistakes are not an option.

What Are the Types of Stainless Steel?

Now, I am going to list the most popular and widely used types of metal. Don’t skip this part as you would know which one needs what treatments or welding process for the best results.

Austenitic Stainless Steel

The most common type is this one which is also known as the 300 series. Its base metal can withstand up to 350 degrees Fahrenheit. Going further into the classification, you would find fully austenitic steels known as 310, 320, and 330 series.

They require more care which you can ensure by introducing low heat input and doing convex welds. That would prevent the metal from cracking. For more detailed information on the type, you can visit this website.

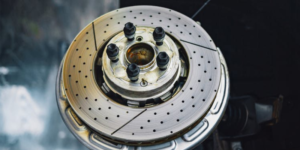

Ferritic Stainless Steel

This type is widely used in the automotive industry, and the 2 most common grades are 408 and 439. You would find the maximum thickness of this material is ¼”.

Furthermore, the maximum interpass temperature of its base metal is 300 degrees Fahrenheit. Those characteristics make it perfect for low heat input and single-pass welding. In case you don’t follow the guideline, you weaken the joints’ strength without realizing immediately.

Martensitic Stainless Steel

As for overlays and building up wear-resistant materials, martensitic stainless steel is widely used. Due to its tendency to hydrogen cracking and hardness, particular precautions are required on the job site.

You should use TIG or MIG welding which is a low hydrogen process. Also, it is recommended to preheat the metal and keeping the temperature between 392 to 572 degrees Fahrenheit. Finally, get to know the micro construction of the material to determine the time and temperature at the post-weld heat-treatment phase.

Duplex Stainless Steel

In terms of heat, duplex and ferritic are almost the same. They can’t take too much heat due to their chemical composition. Duplex SS has portions of both austenitic and ferritic types making the selection of the filler metal slightly difficult.

In reality, you would not find a suitable filler metal for this type as fast-cooling of the fillers than the base metal. You can check out a detailed article on how duplex stainless steel welding is done for more info.

Unidentified Base Metal

Professionals who often have to perform field-repairs come across some stainless steel types whose base metal is unknown. For such cases, you can rely on the 312 stainless electrodes which are developed especially for repairing tasks.

As you have learned that temperature is a crucial factor in welding SS, you should constantly check how hot the piece is. You can either use electronic infrared thermometers, temperature indicating sticks, or electronic surface temperature probes. As soon as it reaches the temperature limit of the base metal, you must stop welding and let it cool down.

What Are the Different Types of Weld Suitable for Stainless Steel?

There are several types of welding techniques available but all of them are not suitable for stainless steel for their unique properties. In this part, I have described different processes and explain why certain methods are recommended by experts.

Can you TIG weld stainless steel?

For a clean, controlled, and nice finish, TIG welding is the most preferred method of welding stainless steel. Despite all the good sides of TIG, lots of people don’t consider it for quick repairs as the process is very slow. For large tasks where time is not crucial and finishing matters the most, you must go for this technique.

Can you MIG weld stainless steel?

MIG welding is a very popular method for its speed and convenience. Even beginners own a set of MIG welding equipment. Only managing a stainless filler, you can be ready. Make sure that the piece you are welding is stainless steel; not a cheap rip-off. Also, don’t use flux core because the shielding gas is necessary for stainless steel welding.

Furthermore, experts recommend using a spool gun so that one can save downtime on the welder. In case, you don’t have any other way than using a mild steel MIG wire, it is a must to coat the surface to prevent rust build-up. In short, don’t use this method unless you have to do some quick repairs or a few small on-the-go welding tasks.

Can you stick weld stainless steel?

The answer is also positive here. Like the other two techniques on top of this one, you can easily stick weld stainless steel workpieces. However, you should be careful about the slag as they tend to fly off.

Can you spot weld stainless steel?

Yes, it is possible to spot weld stainless steel only when the sheets are very thin. Between two electrodes, the sheets are placed on one another and they get welded by pressure and electricity. Unlike other methods, it doesn’t require filler material ensuring a clean finish.

Which Is the Best Way to Weld Stainless Steel?

Well, you have probably understood that there is no straightforward answer to that question. The best results depend on the job nature, the skill of the welder, and material type. I have described the specific type’s nature above so that you can choose accordingly. You can have a quick look at the table below and decide which one to go for.

| Welding Techniques | Best Suited For | Shielding Gas Requirement |

| TIG | Fabricating huge amount of metal, cleaner results, applications where food and health are concerned | Argon or Helium |

| MIG | Small repairing tasks, quick field repairs, applications where a messy finish is not a concern | Carbon Dioxide (CO2) |

| Stick | Indoor and outdoor applications, tasks requiring economical ways to fabricate | Carbon Dioxide (CO2) |

| Spot | Joining two thin sheets or stainless steel meshes | No gas is required |

Can You Weld Stainless Steel to Metal?

Using different welding techniques, you can weld SS to different kinds of metal. It can be mild steel, titanium, copper, or something else. Among several welding methods, you can’t consider resistance or spot welding as electric conductivity varies among dissimilar materials. MIG and TIG are the most preferred ones. Let’s talk about them in detail.

Can you weld stainless steel to steel?

Yes, it is possible to join two different types of steel using either MIG or TIG welding. Among the two methods, MIG is preferred over the others for some benefits. However, it is advised to avoid stainless steel welding to carbon steel due to some reasons. The process is difficult, introduces hot cracking to the SS, may cause thermal expansion, can increase bimetallic corrosion. Also, the joints don’t get strong enough which may lead to serious accidents.

Can you weld stainless steel to mild steel?

It is possible to weld mild steel to SS but the lack of fusion and some slag inclusion can become a problem. Experts recommend using a drag rod such as an E7018 at a 25-degree angle for the best results. One should practice a lot before applying the technique in the field.

Can you weld stainless steel to titanium?

Only in the presence of shielding gas, you can weld SS to titanium. However, it is as simple as other processes. With an expensive setup and a complex fabrication method, you can weld stainless steel to titanium.

Can you weld stainless steel to galvanized steel?

Welding galvanized steel to stainless steel is possible but the zinc used in galvanization can cause a serious problem. When zinc gets molten, it makes an intergranular attack on the SS. And it leads to liquid metal cracking or known as LMC. However, there is a solution and it is by using 20% muriatic acid or other types of acid. The chemical removes zinc before the welding leaving both metals safe for welding.

Can you weld stainless steel to copper?

With the help of a filler material that contains tin and silver, you can join two metals together. The process demands extra care and some precautions. Without maintaining those, you can’t get a strong bond between SS and copper. I recommend you to check out this video and see how experts do it.

What Are Some of The Best Welders That Can Weld SS Metal?

Unless you have enough time to check out my detailed reviews on the best stainless steel welder, you can read a summarized version of it here. Let’s see some of the most popular MIG, TIG, and Stick welding equipment that is suitable for the job.

- Weldpro Digital TIG 200GD – Best TIG Welder for Precise Welding

Very powerful 200 amp machine, AC balanced, fully adjustable pulse, capable of MMS stick welding,

- LOTOS MIG175 – Best MIG Welder with a Spool Gun

Aluminum wire feeder, high-speed MIG spool gun, powerful 175 amp welder, versatile usability, reliable and durable build quality

- ETOSHA MIG160 – Reliable MIG Welder Under the Budget

160 amp MIG welder, overheating protection, IP21 rated, wide applications, advanced cooling system

Conclusion

Have you got the answer to your question, can you weld stainless steel? Always remember to match the type or grade of the filler metal and base metal. Unless you can decide by yourself, you can consult with a welding supply company near your location to find the appropriate filler.

I hope that my research and explanations have covered almost all possible queries. However, I may have missed something. In case you want to know more or have different inquiries regarding the topic, you can leave them in the comments section below.

Related: